Top Seal (Pack), Stretch, Gas Flush, Vac, Map, Skin, Skin Protruding, and Skin Protruding Flatboard.

Unit of Measure

Specifications

|

P5-RGO Base Machine Overview

|

HMI Touchscreen Control Panel Mounted on an Adjustable Arm

|

Electrical Construction

|

Servo Film Management System

|

Tray Sealing (Pack)

|

Modified Atmosphere Packaging (M.A.P.)

|

Vacuum Skin Packaging (V.S.P.)

|

Tray Stretch Sealing (Stretch)

|

Point Five Jargon

|

Additional Information

Specifications

Length |

N/A 3700 mm145.7 in3.7 m12.1 ft |

Frame Construction |

N/A Stainless Steel Washdown |

Electrical Construction |

N/A Ingress Protection (IP65) |

Enclosure Rating |

N/A NEMA 4X |

Cycle/Min (Tray Seal) |

N/A 20 |

Cycle/Min (MAP) (VAC/GAS) |

N/A Up to 15 |

Cycle/Min (VSP) (SKIN PACK) |

N/A Up to 10 |

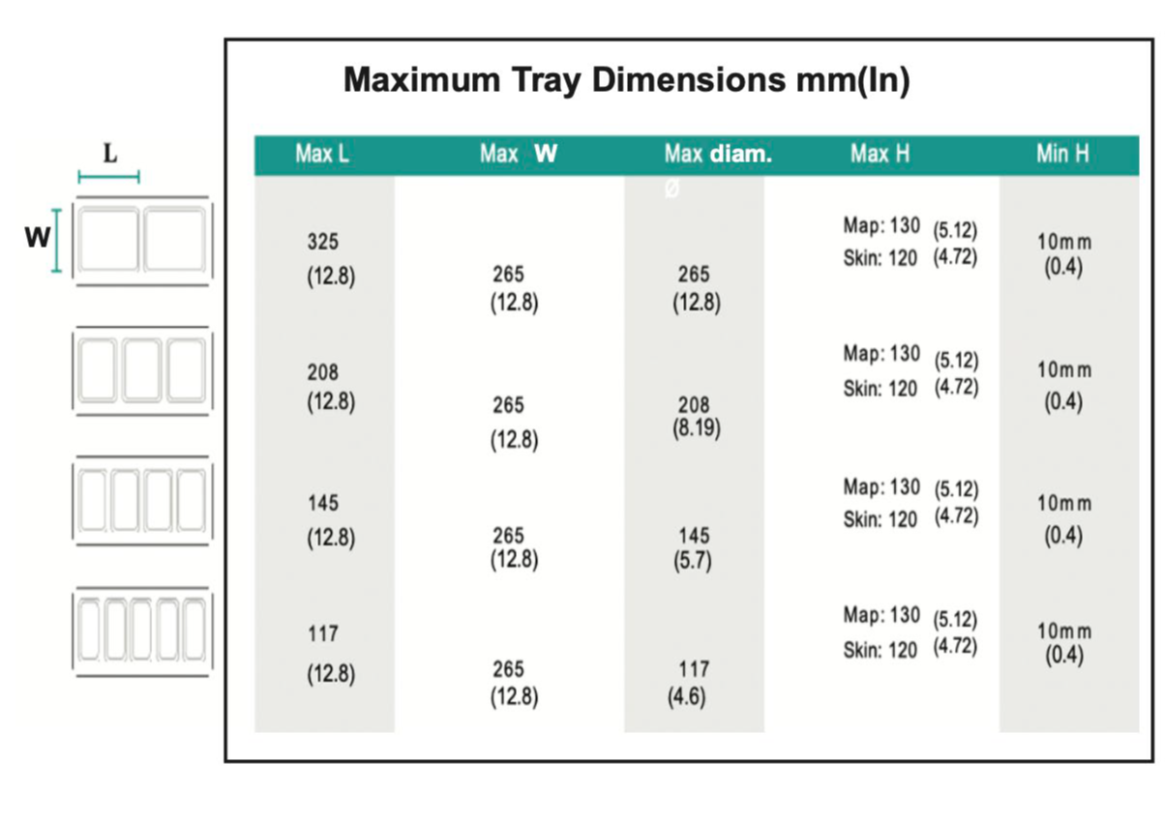

Maximum Tray Dimensions |

N/A

Seal Head Configurations |

Voltage |

N/A 220 V |

Phase |

N/A 3 |

Frequency |

N/A 60 Hz |

Standard Compressed Air Pressure at 15 Standard Cubic Feet Per Minute (SCFM) |

N/A 90 psi |

Maximum Film Width |

N/A 13.4 in340 mm |

Maximum Film Diameter |

N/A 11.8 in300 mm |

P5-RGO Base Machine Overview

P5-RGO Base Machine Overview |

N/A

|

HMI Touchscreen Control Panel Mounted on an Adjustable Arm

Human Machine Interface (HMI) Touchscreen Control Panel Mounted on an Adjustable Arm |

N/A

|

Electrical Construction

Electrical Construction |

N/A

|

Servo Film Management System

Servo Film Management System |

N/A

|

Tray Sealing (Pack)

Tray Sealing (Pack) |

N/A

|

Modified Atmosphere Packaging (M.A.P.)

Modified Atmosphere Packaging (M.A.P.) |

N/A

|

Vacuum Skin Packaging (V.S.P.)

Vacuum Skin Packaging (V.S.P.) |

N/A

|

Tray Stretch Sealing (Stretch)

Tray Stretch Sealing (Stretch) |

N/A

|

Point Five Jargon

Point Five Jargon |

N/A

Top Seal This Seal-Only packaging method seals the film on the tray. VAC This Vacuum sealing method partially extracts the air inside the tray. It is ideal for liquid foods, i.e., sauces or yogurt, and for foods that are immersed in a preserving liquid, i.e., pickles, soups or cheeses. Gas Flush This Modofied Atmosphere packaging method with Gas Flush, replaces the air inside the tray by injecting a gas mixture, as opposed to creating vacuum. Inside Cut The film is cut inside tray edge and does not exceed tray dimension. Film Efficiency Special technical applications help minimize film waste. Efficient Smart Gas Technology The use of additional gas buffer tanks along with time and gas pressure optimization resulting in considerably lower gas consumption levels. Film Perforation A film pre-cutting system along with multi-section tray sealing, allows for multi-product packaging options and increased productivity. Easy Peel Pull Tab Different film shaping options available. An easy-peel corner allows for opening with minimal effort. Air Evacuation Plates Special temperature resistant plates built into the seal head to express excess air inside the package and minimize a balloon effect. Map This packaging method of Modified Atmosphere uses vacuum extraction to take all the oxygen out of the tray, and then inject the desired gas mixture. Skin This Vacuum packaging method uses vacuum extraction to remove all air from the tray. The film is then sealed inside the tray and along its edges. Drawn by the vacuum toward the product, the film fits around it like a second skin. Flat Board Protruding Skin Package where the product may protrude 3-5 cm from surface of flat paper board. Tray Protruding Tray skin pack where the product may protrude 3-5 cm from tray edge. Pre-Heating A system that pre-heats the film for higher stretchability prior to entering the seal process Anti Sloashing A system that adjusts chain movements to minimize product oscillations, thus allowing trays to be moved quickly, safely and smoothly without spillages. Ideal for liquid products such as sauces and soups. Seal Tool Storage Cart Stainless steel cart allows for a quick and safe tool change, safe storage and maintenance.. Data Management Intuitive, user-friendly, custom-made panel. Suitable for 4.0 integration. App/PC controlled interface with teleservice options. SD card port. Stretch Sealing of a stretch film on the tray flange with product protrusion, also with the possibility to have modified atmosphere inside the pack. |

Additional Information

Additional Information |

N/A

Precision, Power, High performance Lower Energy Consumption All motors, except the chamber lifting mechanism, are connected to a planetary gearbox which increases motor torque, efficiency and accuracy Easy Access

|