1158 Tower Lane

Bensenville, IL 60106

Phone: 847-678-5016

Email: info@p5pkg.com

Website: www.p5pkg.com

Applying chipboard sleeves to your trays or cups is typically one of the most labor intensive operations

in your packaging and production line. This necessary but highly expensive operation is often a considerable

bottle neck that limits line efficiency and output. The P5-SLV automatic sleeve applicator is your solution.

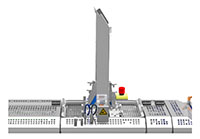

Designed to handle pre-glued sleeves, the P5-SLV can be integrated into any packaging line. Capable of

production rates of 50 per minute as a single lane system or up to 100 per minute in the dual lane

configuration the P5-SLV handle a wide range of tray and cup sizes. For added flexibility, the dual lane system is capable of running each laneindependently thus running two products at once. The compact system design is caster mounted for easy portability with a variety of infeed and discharge options available.

Affordable sleeve hoppers can be customized to suit your specific sleeve, are light weight and easy to change over.

| Items |

P5-SLV (Single Lane) p5-slv |

P5-SLV (Double Lane) p5-slv |

||

| Electrical Capacity | N/A 1.5 kW | N/A 2 kW | ||

| Electrical Requirements | N/A 208-230V 3ph 60 HZ | |||

| Air Pressure | N/A 90 psi | |||

| Production Capacity | N/A 50 packs/min | N/A 100 packs/min | ||

| Changeover Time | N/A < 5 min | N/A 7-10 min | ||

| Speed | N/A Up to 50 Trays per minute | N/A Up to 100 Trays per minute | ||

| Image |

N/A

Size Illustration |

|||

| Sleeve Dimensions |

N/A

sleeve-dimension |

|||

|

|

||||